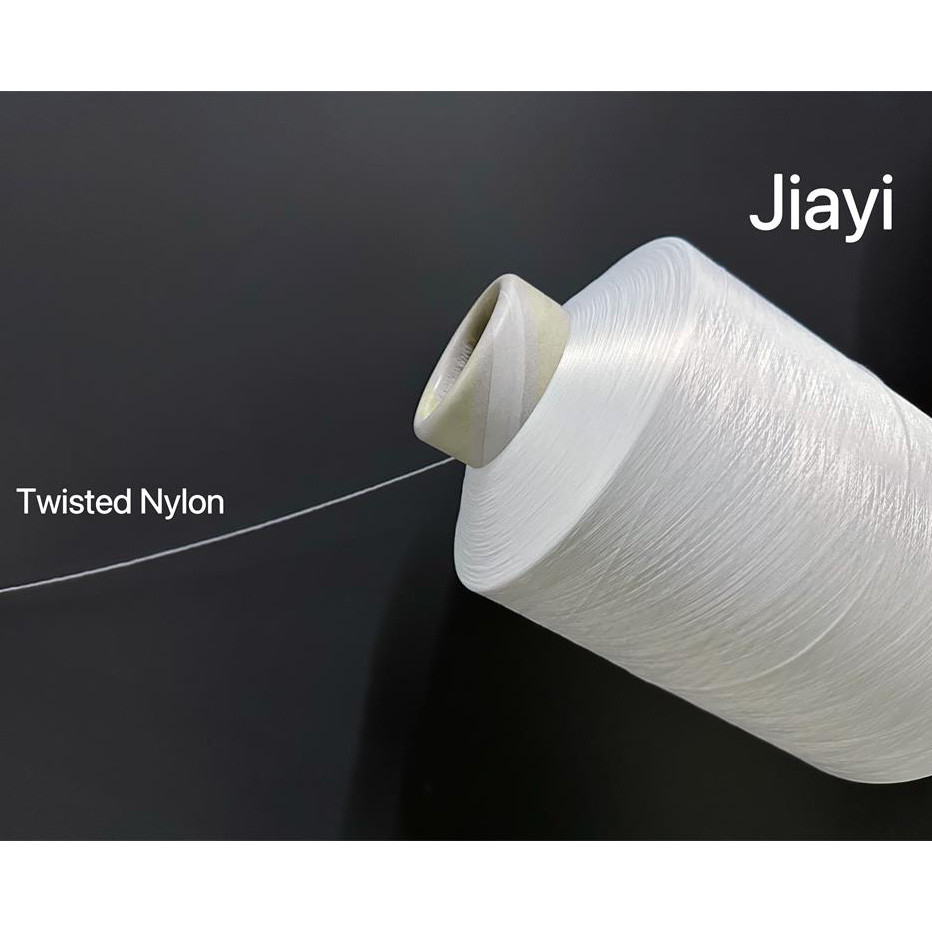

Nylon Twisted yarn

What is Twist in nylon yarns

Twist is simply the spiral arrangement of yarns around the axis of the yarn. Through twisting, the yarns are bound together and create a stronger yarn. The number of twists involved is normally referred to as turns per inch or turns per meter(tpm).

Does twisting increase the strength of nylon yarns?

From the ANOVA results, it is found that with an increment in twist level of the yarn, there is a significant increment in tensile strength, abrasion resistance, and pilling resistance of the fabric.

Twist is simply the spiral arrangement of yarns around the axis of the yarn. Through twisting, the yarns are bound together and create a stronger yarn. The number of twists involved is normally referred to as turns per inch or turns per meter(tpm).

What products required twisted nylon yarn?

For webbings, labels,hank dyed yarn, twisted nylon yarn greatly reduce the difficulty of direct processing with nylon yarn.

Sometimes, there are some fabric or cloth requires this style,then twist nylon is also your good choice.

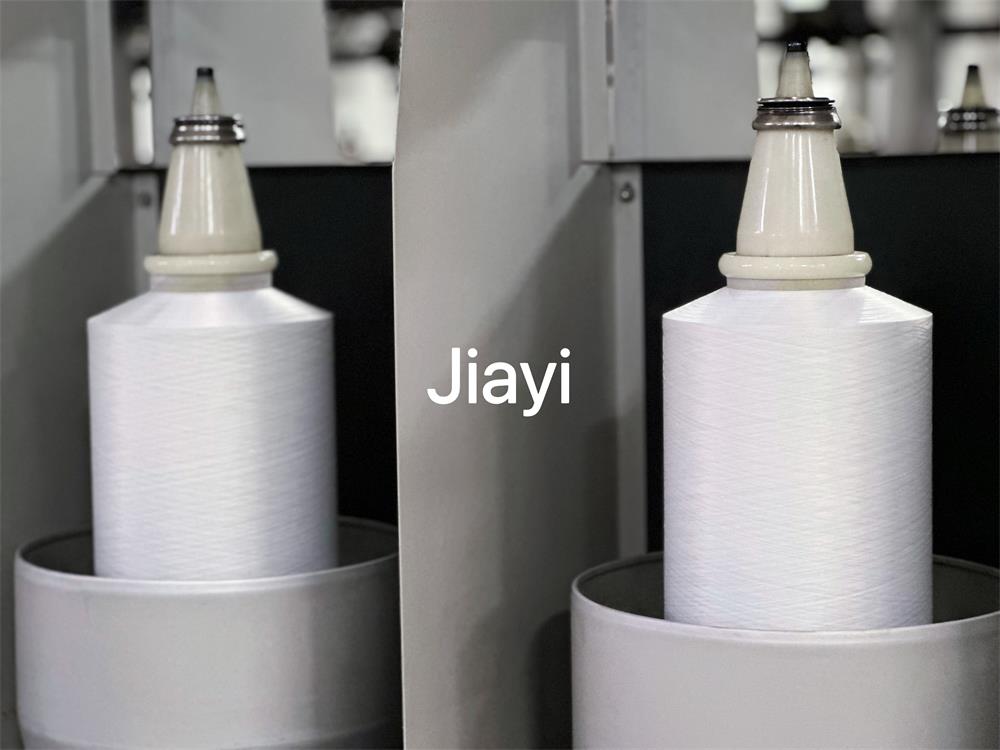

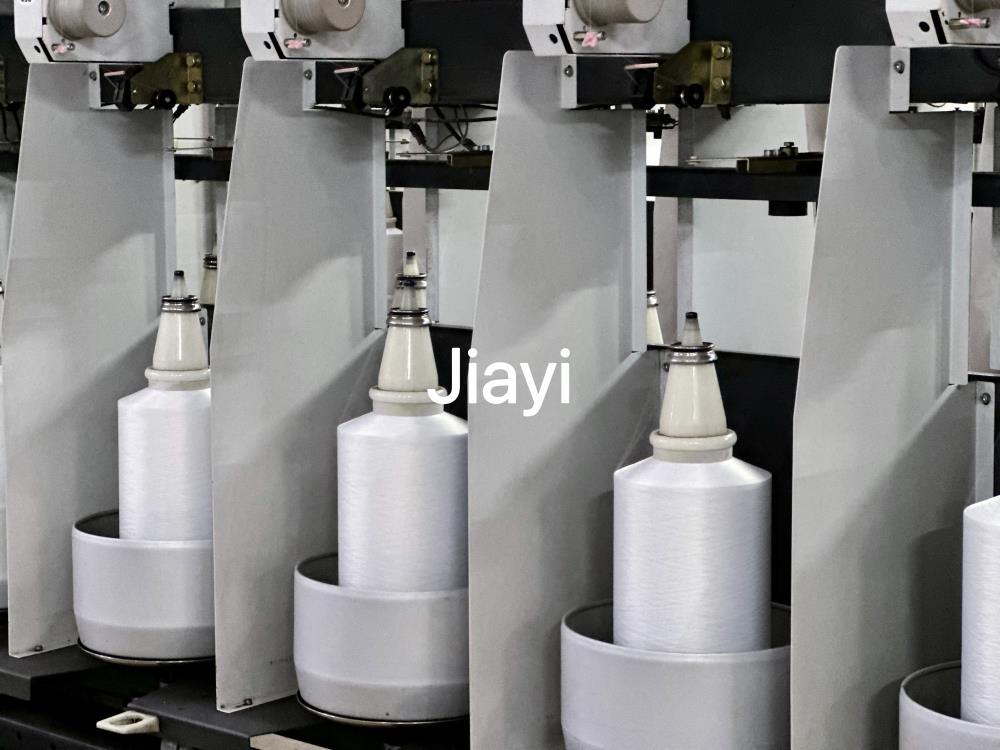

What is Jiayi’s biggest advantage on this twisted nylon yarn:

We have our own twisting machines production lines in the texturing workshop, which ensures the nylon yarn can go directly to the twisting machines under the setting temperature and moisture conditions. It, to the largest extent, keeps the yarn quality good and stable.

Unlike some other twisting machines factories, they buy nylon yarn from other nylon yarn factories to process twist nylon then sell, we transit our nylon DTY to our twisting machines inside our factory, which can largely shrink the cost for our client to have competitive buying price.

What Spec.s we are supplying:

We normally have twsited yarn as following spec.s:

70D/24f/2,100D/36f/2 with tpm 120, tpm110, tpm80 in stock for our clients easy purchasing and shorter leading time.

Related PRODUCTS

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top